Golden Jubilee: Bob Taylor, Richard Hoover, and Dana Bourgeois Reflect on 50 Years of Guitar Making

The world was a very different place when Bob Taylor, Richard Hoover, and Dana Bourgeois began building guitars. “It was the 1970s,” recalls the Maine-based Bourgeois, who started with his father’s tools long before co-founding Schoenberg Guitars in 1986 and opening his eponymous shop in 1992. “There was no internet, no guitar schools, no decent how-to books, no luthier schools, and no local luthier organizations.”

What there was in abundance, however, was demand. The 1960s had made the guitar into a pop-culture phenomenon. But by the following decade, major American makers were struggling. Many players considered the instruments coming from the established factories to be inferior to those they made decades before. Based largely on American classics, imports had been improving in both quality and reputation while remaining more affordable than domestic brands.

Playing techniques were evolving too, fueling a demand for instruments with faster necks, better intonation, and onboard electronics. Rough terrain for the major manufacturers proved to be fertile ground for young builders like Bourgeois, Taylor (founded 1974), and Hoover (who started the Santa Cruz Guitar Company in 1976), among others.

I caught up with all three luthiers via Zoom, with Taylor and Bourgeois on the same call. And although Hoover’s interview occurred a few days later, the conversation dovetailed almost seamlessly with his colleagues. The result is a virtual roundtable highlighting both contrasts and shared experiences. Taken from more than two hours of conversation, the following has been edited for clarity and brevity.

Look back to the beginning of your respective careers and try to imagine what your younger selves would make of the acoustic guitar industry as a whole today—and your own evolution. What would have surprised your younger self the most?

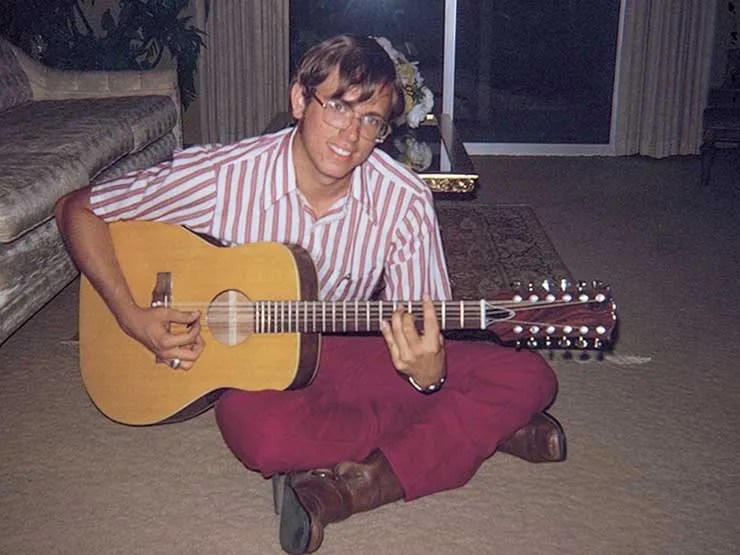

Bob Taylor: What would have surprised me is that I’m still making guitars [laughs]. I built my first guitar at 16, so that’s a hard question to answer because I was just trying to figure out how to put in a fret! I don’t have anything that the young Bob Taylor would want to ask the old, wise Bob Taylor, except, “How do you put in a fret?”

Dana, what about you?

Dana Bourgeois: Well, same thing. First, I’d be pretty surprised to learn that people would pay more than about $400 or $500 for a guitar—even taking inflation into account. The value of guitars seems to have shot up. We sell an average guitar for what we used to pay for a car back in those days—kind of crazy.

Richard Hoover: When we started Santa Cruz Guitar Company, I was 25. And from that perspective, as a young man, I pretty much thought practice was for people who weren’t as smart as me, that I could pick it up right away. I thought I knew a whole lot more than I do now.

Bourgeois: I bet you had the same experience—that it was actually pretty easy. Back in the ’70s, you could make at least a marginal living [repairing or building guitars] while doing what would be considered pretty mediocre work these days.

Was there a specific instrument that inspired you?

Taylor: I was listening to people like Gordon Lightfoot, Peter, Paul and Mary, and Neil Young playing 12-string, so I wanted a 12-string guitar. I saw an imported guitar, an Eko Ranger, at a local store. This thing had a thick polyester finish on it. I didn’t know that was bad. It had a Fender-style bolted-on neck; I’d never seen a Fender, so I didn’t know what Fender-style was at the time. But it was really easy to play; the neck was skinny and the strings were low. It cost $179. I couldn’t afford that. But I had already won the industrial arts exposition in California twice for metalworking in junior high school. I could make things. So I thought, “Well, I’ll just make one in wood shop.”

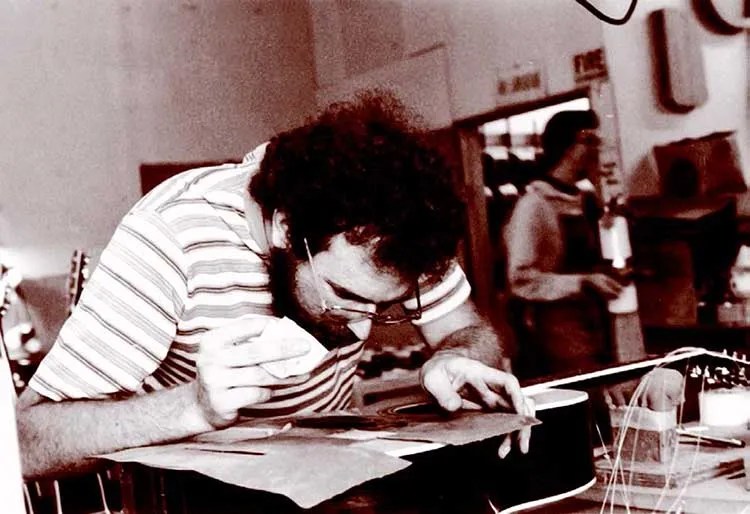

Bourgeois: For me, I was browsing around in a bookstore and I ran into Irving Sloane’s Classical Guitar Construction. This was in 1973 or ’74. My dad was an amateur woodworker, and my grandfather was a machinist. I had always been around tools but never had any interest in using them. But I did play the guitar, and looking through this book I thought, “Gee, that might be fun. I bet I could make this thing with some help.”

The book turned out to be horrendous in a lot of ways as a how-to book! But I got through it and made a few classical guitars. Then Sloane came out with a book on steel-strings, which is what I always wanted to build. I had the opportunity to acquire a really beat-up 1963 Martin D-28. I worked putting it back together, asking more experienced people for advice on how to do it. It was just head and shoulders above anything I’d ever played or imagined. And I just wanted to build guitars that sounded like that. I built a few more guitars that didn’t sound like that, and it’s been a quest ever since.

Hoover: When I started out, the only body shape for a guy was a dreadnought. We’d been conditioned for that by our guitar heroes: When you got to a certain point, you got the big one; you got the real guitar, a dreadnought. But it had its limitations. It was built for volume, built to be the rhythm in a band. It was the drums.

When guitarists like Dan Crary, Norman Blake, Doc Watson, and Tony Rice started playing single-note lines, they brought the dreadnought forward and started taking over the fiddle leads. But the instrument was bass heavy, a little woofy and tubby. It really didn’t present their work in the best light.

Also, we had the phenomenon of new acoustic music. People were playing really complicated sophisticated arrangements and using open tunings. They needed subtlety and better separation of notes to present their work. And the [traditional] dreadnought was not the instrument for that.

ADVERTISEMENT

Our first guitar was very much a Trojan horse. It looked like a dreadnought but was voiced more like an OM. It played with a more balanced EQ and therefore had more definition and separation of notes. It was a real tough sell at the time because it didn’t have that boomy, powerful bass that people look for in a dreadnought. But the more sophisticated players realized the advantages of it. So that was the guitar I thought the whole world would embrace. We could foist our values on everybody else!

It’s interesting that Dana and Richard were inspired by the tone of the traditional dreadnought in different ways. Bob, did you also have a tone in mind?

Taylor: Dana’s original story is that he wanted to make a guitar that sounded like that Martin. My original story is I wanted to make a guitar that played like that Eko Ranger. Sound wasn’t in my equation.

By the time I got my first Martin, I had already built three guitars, using the Irving Sloane classical book to make steel-strings that were like high-school-kid projects. I went into a store and saw this beautiful Martin. I couldn’t imagine building something that was made that well. I sold my motorcycle and bought that guitar for $450. I wanted to make a guitar that played like that Eko Ranger but that was as clean and well-crafted as the Martin.

Building guitars for yourself is one thing. Turning it into a business with a line of consistent models is something else. How did that evolve?

Taylor: I had a job at a shop called American Dream. The guitars the guy made were crude, but they had kind of a unique sound. He showed me a few things, and we were up and running with Taylor guitars. People would pick them up and go, “Wow, this thing plays great. I like that it’s not too bassy.”

Finally, the day came when we approached some dealers. Well, that was scary. We went up to Los Angeles with a trunk full of guitars. McCabe’s Guitar Shop, which is still around, liked that the sound was treble-forward. “Could we give it more? I want the sound to cut through.” I’m like, “Yeah, OK.” I’m 21 years old. I don’t know how to make a guitar that has more treble!

Then we found Westwood Music, owned by Fred Walecki, a cool guy famous with the Laurel Canyon scene of the time. He would give a guitar to Glenn Frey or Jackson Browne or whomever and be like, “Just make me some weekly payments.” He was like their angel investor.

Fred liked my guitars, started buying them, and sold them to people like J.D. Souther, David Crosby, Neil Young, and the Little River Band. They bought my guitars because they liked how they played. Most of them were electric players who found [traditional] acoustic necks too clubby, the action too high, the intonation bad. And that’s how I learned my guitars were easy to play: because players told me.

Bourgeois: My association with Eric Schoenberg and C.F. Martin & Co., during my tenure as co-founder of Schoenberg Guitars, opened a lot of doors in the public recognition arena, eventually allowing me to head off on my own. During my tenure with Bourgeois Guitars, my associations with guitarist Bryan Sutton and multi-instrumentalist Ricky Skaggs probably brought the most public awareness of my guitars.

Hoover: At Santa Cruz, we started out as custom builders, making guitars-to-order for individuals. And over the years, because of the vagaries of the market and the demand, we were forced into making standard models as a mode of survival. Before the internet, we could only sell guitars to the people that we’d influenced personally—local people. Advertising in a mass-circulation magazine was beyond our budget.

The boutique concept was not even fully formed yet. We were really pioneering a way of building that our customer base wasn’t used to. We made a couple of guitars for players like Tony Rice and Eric Clapton. So people started calling me asking for a guitar just like we made for Tony. And my answer at the time was, “Oh, sorry, we’re a custom shop. That was a one-off—what would you like for your own guitar?”

People would say “Thank you very much,” and hang up. Eventually I realized if we made a guitar based on the one we did custom for Tony Rice, people looking for that sound would buy it. And that was a good lesson in marketing. But we also learned that if we made the same models as bigger competitors, customers wouldn’t be able to distinguish between them or be willing to pay our higher prices without testing them.

Today our catalog doesn’t have a list of models. We list body shapes of basic custom instruments and a menu of accoutrements you can add to that. So our prices start for a basic custom guitar and people fill in the gaps. And now we’re in our ideal spot.

Taylor: Consistency was hit or miss [at first]. John Carruthers, the repairman at Westwood Music, taught me a little bit about refretting. Then I met Jean Larrirvée and we became friends. They helped me get the whole guitar together—with a great fretboard, using the right fretwire—and the guitars started holding up [over time], though not perfectly.

Early on, you’d send a guitar to Japan, go there two years later, pick that guitar up and look down the neck, and you’re like, “Oh, my God, it’s so warped! How are we gonna fix this?” And Dana will probably corroborate, but there is no magic turning point. It’s a game of inches. It’s death by 1,000 paper cuts.

Bourgeois: Agreed. One thing we have on our side these days is that the dealers know more about climate control. Back in the day, no one knew anything about it. When I started out, I didn’t build very many guitars. I made my living as a repairman. So I learned the hard way what can happen to a guitar. And I probably bought a lot more wood than I was able to use. I was always building a guitar, selling it, building another one, kind of slowly. But if you sit on wood for a long time, it acclimates. Here in Maine, we have cold, dry winters and very humid summers. So the wood is exposed to a bit of everything.

Like Bob, I learned the hard way what can go wrong just by not paying attention or by not understanding moisture levels and wood and climate control. But these days we’re shipping guitars all around the world. And no matter how well you take care of them there’s no guarantee that the customer will do the same.

Speaking of wood, is it more challenging to get your preferred materials now than in the past?

Hoover: Bob’s needs for materials is really different from ours.

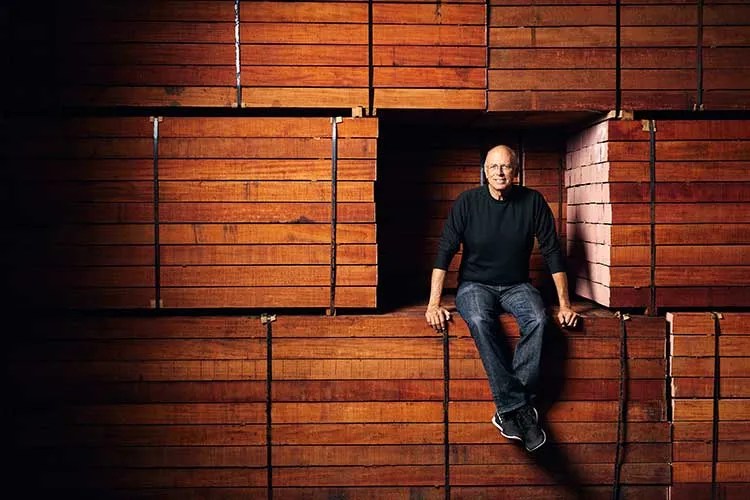

Taylor: They and I do a different thing. They build fewer guitars, and every one of them is a bench-made guitar. We make 1,000 guitars a day. Let that sink in for a second. You can go right past that. But that’s 20,000 fret slots a day.

Your fretting elbow must really shot, Bob!

Taylor: Oh my gosh: It takes me all the way till noon just to fret those thousand guitars [laughs].

But when we’re talking about materials, and specifically wood, with our volume, it takes a lot of different kinds of woods just to get the job done. We’ve had to look at new legal sources for wood and even start planting trees and thinking about the future. We’ve been using urban wood from city streets.

We also rely on a lot of tops that are not spruce. We make koa tops; we’re starting to make ash tops; and we make mahogany, walnut, maple, and cedar tops. And without that right now, there just wouldn’t be enough spruce for us to make our guitars.

ADVERTISEMENT

If you’re focused on a more traditional kind of build, like that D-28 sound Dana mentioned earlier, are those woods hard to acquire nowadays?

Bourgeois: Brazilian rosewood can be. But we build 400 guitars a year. It would take us more than two years to build what Bob does in a day. We’re willing to pay a pretty dollar for good-quality materials. And so far, we haven’t had a materials problem. We have longstanding relationships with suppliers and oftentimes materials find us through those contacts.

But materials have changed. Though it used to be commonplace, old-growth wood is exceedingly difficult to come by. New species of wood are constantly being introduced. Back in the day, for example, all Martin guitars were made of red spruce, Brazilian rosewood, mahogany, and ebony. We now keep stocks of over 40 wood species.

Hoover: Back before there were supply houses for luthiers, it was a lot of work to get our materials and develop relationships. But now we get the benefit from that. In several cases, we’re on the third generation of families that sell us our tonewoods. They’re about sustainability and the environment for practical reasons. The value of that is incalculable. That is personal friendships, long history, trust.

Another part of that is I don’t hesitate to tell people where get I wood. If I turn them on to somebody like Bob, that can change their life—and they’re not going to sell the materials to Taylor at my exclusion. They’re going to make sure I get what I need out of gratitude for helping their business. Do right by others, they’ll do right by you.

So our sourcing of materials is more at the top of the food chain, rather than the bottom. Just take as an example buying walnut or redwood: I can put out $5,000 or $10,000 at a time. Maybe ten percent is suitable for our guitars, but we can sell the rest and end up with a great deal on the wood that we got.

There’ve been lots of challenges and environmental regulations and so forth over time, but they’re all surmountable. Sometimes it’s just administrative drudgery. But for hard-to-get materials like Brazilian rosewood or koa, we’re really well connected on those.

Still, we’ve seen more and more acoustic guitars featuring nontraditional tonewoods. Is that challenging?

Taylor: For us, it’s a long, arduous process. It can take three to five years. I can go to when we decided to explore Tasmanian blackwood, a cousin to koa. The first question is: Does it make a guitar? So you get one piece of it. You make a guitar. Yes, there’s potential here. Next: Can you buy it? What if we can’t get enough? So I might buy a year or two years’ worth of this stuff before I ever introduce it. Then I tell whoever is cutting it to stop cutting. “You have to wait for me to get back to you because I have to find out if I can sell it!” It then can take two years before we figure out if we can sell it. Another example: the Urban Ash model took three years to develop.

Richard, you mentioned the different need for materials between you and companies like Taylor. Yet you also have been using nontraditional woods.

Hoover: It can be practical. And sometimes, a spiritual practice, too. The guitar can be a vehicle. We’ve got a message to give, and part of that message is environmental responsibility. When we introduce a wood that is more sustainable and has less impact on a tropical environment, that’s a good thing. And because of our status in the marketplace today, we have credibility. We couldn’t have done this earlier.

Koa is a great example. We started building with koa in the mid-’70s and nobody knew what it was. It was a really, really hard sell. It took conversations with Chris Martin and Bob Taylor for them to give it a try. And when they introduced it, all of a sudden it became OK [in the wider market], and then we’re off and running with it.

I’m always looking for woods that are sustainable, maybe more domestic, so we don’t have to go through as much shipping and things like that. And part of that practice is to educate people in the value of woods like walnut, which is a beautiful tonewood, but there’s not much history to convince people of that until we put it in a really nice guitar.

Bourgeois: So, my whole philosophy of sound is if you have a building style—and I’ll bet Bob and Richard agree with this after all the wood experimentation they’ve done—if you build it right, the guitar sounds more like the wood than anything else.

How much have the customers—players or collectors—influenced your designs?

Bourgeois: Quite a bit. I’ve always believed that the value of a guitar lies in the way it sounds in the hands of a good player. I’ve always tried to get guitars in the hands of the best players I have access to and to listen to their feedback, even if it’s painful—which it often was in the earlier days.

Hoover: There’s nothing like having built guitars out of different woods, observing them and what’s different about them, but a good shortcut for readers is the internet Wood Database. You can look up most every wood and get accurate information on its workability. Does it crack or warp? Is it hard? And you can actually predetermine what tone to expect out of it on the scale of bright to dark.

Taylor: Once we started making good-sounding guitars, I never felt the need to be working on getting the next better-sounding guitar that would make this or that player raise his or her hand: It might make another player take their hand down.

I’ve always thought of my craft, my art, as a business—with business goals. When I started hiring people, one of my major goals became to not only make good guitars but to bring the company to a point where someone could come and work here and have a career. Right now, I’m proud to say our company is 100-percent employee-owned and we have legitimate careers.

I was driven by a natural inclination to tweak the process. Operational excellence and process excellence are things I can never get away from. I realized that I stumbled across a second flavor. I refined that and thought holistically about the whole package. We were among the first after Takamine to use electronics, and to this day, we kind of rule that roost.

ADVERTISEMENT

But I have to say that with [master guitar designer and owning partner] Andy Powers working at Taylor, we have as good a player as there is and as good a guitar maker as there is, and he’s improving the sound of Taylor guitars.

Bourgeois [to Taylor]: You found a great guy. By the way, I knew Andy before he worked for you, and I’ve always been impressed with both his building and his playing.

Bob is right in that no matter what direction you push the sound, some players are gonna love it; some players aren’t. It’s impossible to reach this ideal that everyone is going to want.

How big of a role does technology play in today’s guitar building?

Bourgeois: Across the industry, building techniques have changed. Almost nothing is made the way guitars were constructed in the mid-19th-century. Philosophies have certainly changed. Guitars have to play in tune now! They have to be built lightly enough to respond freely yet also withstand moving from one environment to another. And they have to sound broken-in out of the box. You can’t simply produce an exact copy of a vintage guitar and expect it to do all those things.

Someone once said, “My hearing hardware has constantly degraded, but my software is constantly upgrading.” As you learn to listen you become aware of greater subtleties. Lately I’ve started correlating resonance imaging with what I’m hearing from finished guitars and by tapping tops. The resonance image produced in my head is nowhere near as detailed as images produced from sophisticated software, but it’s nice to learn that it’s usually roughly accurate.

Taylor: Sometimes people ask me, “How many machines do you want?” As many as I can possibly afford! We’re living in this micro-manufacturing age that is magic—so much different than any age that came before us. When CNC came around to me, the only people using them were heavy industry—aerospace, automotive, those kinds of companies.

Bourgeois: And now you can buy one at Woodworker’s Warehouse.

Taylor: I embraced everything I could to improve the process—I developed it, I invented it, I thunk [sic] about it nonstop—because guitars do not have a very well-developed procedure for making them, compared to anything else that you can just go to Target and buy. If you can develop a machine, for example, that bends sides both faster and better, it kills two birds with one stone.

Hoover: The large percentage of instruments are made by a formula of dimensions. You make the top this thick, the sides this thick, you shape the braces like this, and you’re going to get an instrument. When it sounds good enough to write a song and change the world, that’s great.

But if you want the guitar that you’ll keep forever, that can be done by design, and you don’t have to wait until the guitar is done to see what you get. Instead of making the instrument by a formula of dimensions, you make it by building everything to the proper frequencies, like you’ve made a chord on a piano.

Each guitar you make is going to have that great quality of sound, while controlling the shape of the neck, the string spacing, the cosmetics, and the type of wood. That’s where a serious custom builder can do the service for you, create an instrument that would take blind luck to find in a store. Very few people are willing to do this kind of work because it is really hard to manage. But we have had a lot of practice, and we’re good at it.

How would you advise a young builder today?

ADVERTISEMENT

Hoover: One of the things that I learned from my mentors very early on is that there are really no secrets in acoustic guitar building. You might as well start out with that premise, and share openly with other people, because the return on that’s incalculable.

Bourgeois: Earlier we were talking about the whole lutherie culture—how we learned, how things have changed. There was a really big turning point that gave us young upstarts a big boost. And that was when we all got to know each other. This was probably more in the ’80s. We spent the ’70s and the early part of the ’80s just learning our craft. There was no internet back then, there were no luthier conventions, and the guitar books were not very good. But once a lot of us got together and started talking shop, sharing our experiences, and admiring each other’s work… man, this industry took off!

Taylor: And thank you [former C.F. Martin & Co. fixture] Dick Boak and Martin for organizing the Association of Stringed Instrument Artisans.

Bourgeois: Today, I’d advise a young builder to go to a guitar school. There are a couple of good ones out there. Then spend some time working with an established builder, whether it be a small shop or in a factory. If you can, there’s an opportunity to learn an awful lot in a fairly short amount of time. Bob, you’ve always had an open door. I’ve heard quite a few say, “I got a great tour of the Taylor shop. And he showed me around back, shared data…”

Taylor: We have taken different paths in a business sense, but we haven’t taken different paths in our love of building a guitar and wanting to tweak it, and then wanting to brag about it with each other. And we share ideas. But with Dana and Richard, there’s a lot of them in the instruments. And mine is a lot more like a process where we all come together, we build a factory, and we fill the factory with trained people who understand our process and want to make careers here together. But I like factory guitars. In fact, the most valuable guitars that you could go out and buy are [vintage] factory guitars with brand names on them.

Hoover: We have had this compound interest of goodwill with the rest of the guitar-making community and our customers going on five decades now—of people sharing information with us. And we get better and better and better at what we do.

This article originally appeared in the May/June 2022 issue of Acoustic Guitar magazine.